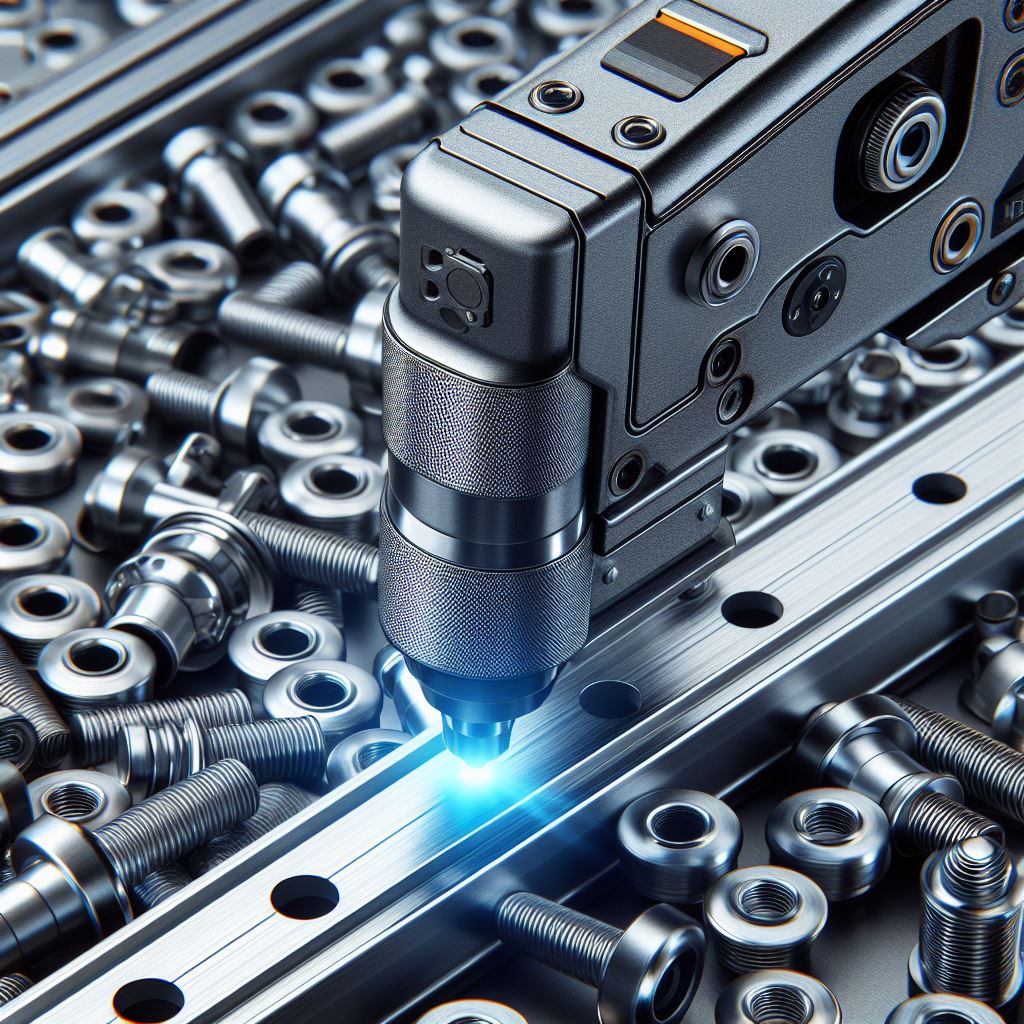

Laser-assisted self-piercing rivet for joining aluminium and steel sheets

A laser-assisted self-piercing rivet that can join aluminium and steel sheets in a single step. The rivet is made of aluminium and has a conical tip that can penetrate the steel sheet with the help of a laser beam. The laser beam heats up the steel sheet locally and creates a hole for the rivet to enter. The rivet then expands and forms a mechanical interlock with both sheets. The laser beam also melts a thin layer of aluminium on the rivet surface and creates a metallurgical bond with the steel sheet. This way, the joint is strengthened and the formation of brittle intermetallic compounds is minimized.

- It can join aluminium and steel sheets with different thicknesses and properties.

- It does not require any pre-treatment or coating of the steel sheet.

- It has a high productivity and flexibility, as it can be performed with conventional resistance spot welding equipment and a laser source.

- It has a low heat input and distortion, as the laser beam is focused on a small area and the rivet acts as a heat sink.

- It has a good joint performance, as it combines mechanical and metallurgical bonding mechanisms.

Laser-assisted self-piercing rivet for joining aluminium and steel sheets

A laser-assisted self-piercing rivet comprises an aluminium rivet body having a conical tip and a flange, and a laser source that emits a laser beam along the rivet axis. The rivet body is inserted into a conventional resistance spot welding gun and aligned with the sheets to be joined. The sheets comprise a steel sheet on the bottom and an aluminium sheet on the top. The laser source is activated and the laser beam impinges on the steel sheet, creating a hole for the rivet tip to enter. The rivet body is then driven into the sheets by the welding gun, forming a mechanical interlock with both sheets. The laser beam also melts a thin layer of aluminium on the rivet surface and creates a metallurgical bond with the steel sheet. The laser source is deactivated and the welding gun is retracted, leaving a strong and durable joint between the sheets.